Since 1995, Raptech has been delivering customized and technically viable engineering solutions to leading global automotive companies. We offer a diverse range of high-quality engineered products, consistently striving to address our clients' complex needs with innovative solutions.

Leveraging extensive expertise in design and manufacturing, Raptech offers a wide range of solutions for intricate fixturing needs. Our robust processes ensure that you achieve the precise accuracy required for your end products.

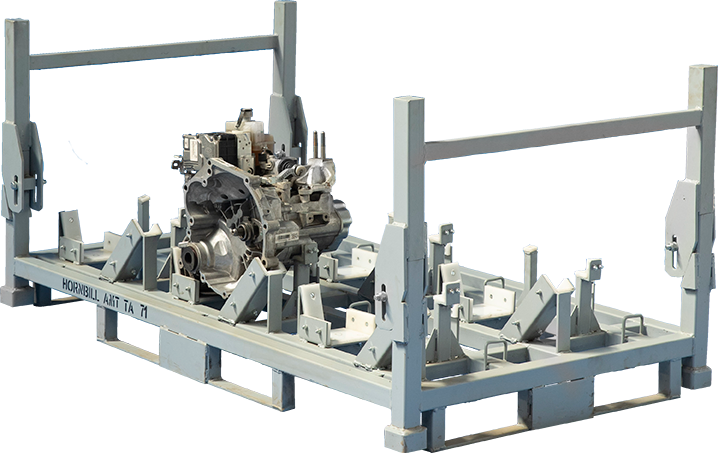

Raptech’s material handling solutions are developed through a meticulous understanding of each customer's manufacturing environment. We design multiple versions to deliver the most effective, durable, and optimized solutions, ensuring a continuous and seamless flow of goods.

At Raptech, we are dedicated to fostering a culture of continuous improvement, teamwork, and a proactive approach to challenges. Our commitment to excellence is reflected in our world-class infrastructure, highly skilled team, and a workforce that excels in delivering tailored engineering solutions across six crucial categories for the global automotive and logistics industries.

Efficient material handling is pivotal for optimizing production and logistics processes. At Raptech, we provide state-of-the-art material handling solutions designed to enhance efficiency and safety in various environments. Our solutions include advanced conveyor systems, automated storage and retrieval systems, and custom-designed equipment that streamline the movement and management of materials. Our expertise ensures that our clients can handle large volumes of materials with minimal downtime and maximum reliability.

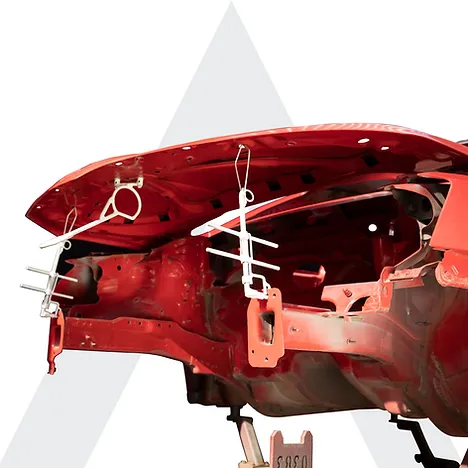

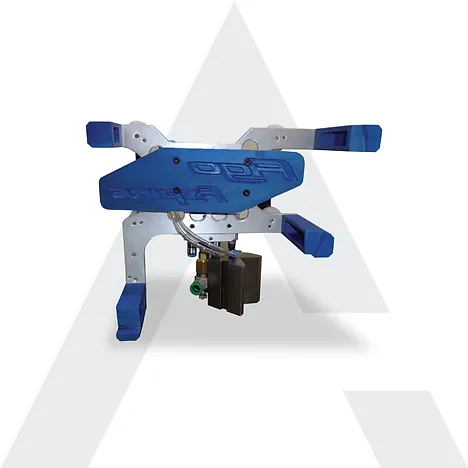

Paint Shop Jigs are crucial for achieving uniform and flawless paint application on vehicle bodies. Raptech excels in providing these vital solutions within the automotive sector. We specialize in crafting both metal and plastic Paint Shop Solutions, meticulously designed for robotic painting. Leveraging our extensive industry experience and technical expertise, Raptech is a trusted partner for automotive industry paint shop needs.

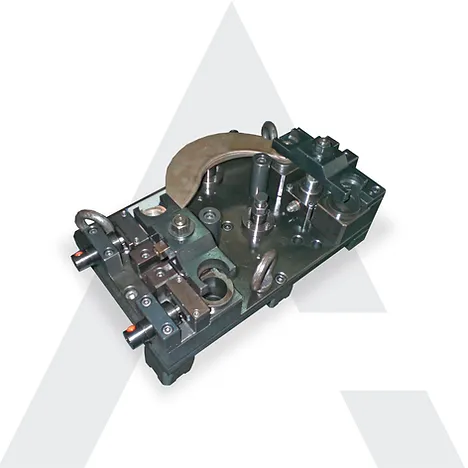

Fixturing solutions are essential for engineering and ancillary industries, providing application-specific support that ensures precision, durability, and consistency in the manufacturing process. These solutions enhance product uniformity and interchangeability. Raptech produces fixtures that are robust, versatile, and highly functional.

Vehicle assembly is a crucial stage that requires specialized tooling. For OEMs to effectively launch their next product range, having the right assembly tools is essential. At Raptech, we utilize advanced technology and infrastructure to produce precise and reliable tools for this purpose.

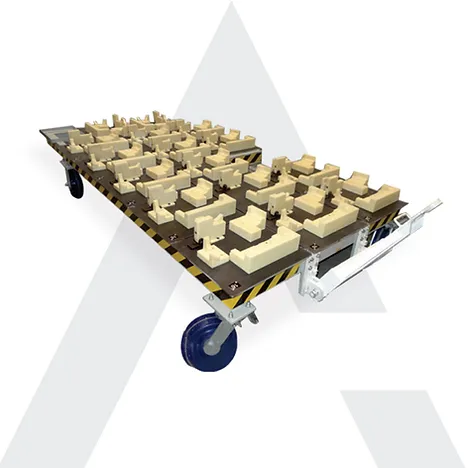

A Front End Carrier Storage & Transport Trolley is a specialized piece of equipment designed to streamline the movement and organization of goods in various settings. Used to transport items from one area of the warehouse to another. This could include moving goods from receiving areas to storage locations or from storage to shipping areas.

A Gear Box Handling Trolley is specifically designed for the transportation, storage, and handling of gearboxes, which are critical components in machinery and vehicles. Used in automotive manufacturing and repair shops to transport gearboxes to and from assembly lines or maintenance areas. It helps in reducing manual handling and improving safety.

The Piller Lower LH/RH Handling Trolley is crucial in industries where heavy and sizable components need to be moved or positioned accurately. Its design focuses on improving efficiency and safety, adjustable platform for the transportation of lower pillars or supports, this trolley enhances operational workflows and reduces the risk of damage.

A Dashboard Panel Storage & Transport Trolley is a specialized trolley designed for the safe handling, storage, and transportation of dashboard panels, which are crucial components in automotive and other machinery applications.

The Piller Assembly Transport Trolley is a specialized piece of equipment used primarily in industrial settings for transporting and storage, particularly those related to electrical or mechanical systems.

A Scissor Lift Trolley is a versatile material-handling device designed to lift, position, and transport heavy loads safely. It features a hydraulic lifting mechanism, durable platform, and easy maneuverability, making it ideal for workshops, warehouses, and industrial maintenance tasks.

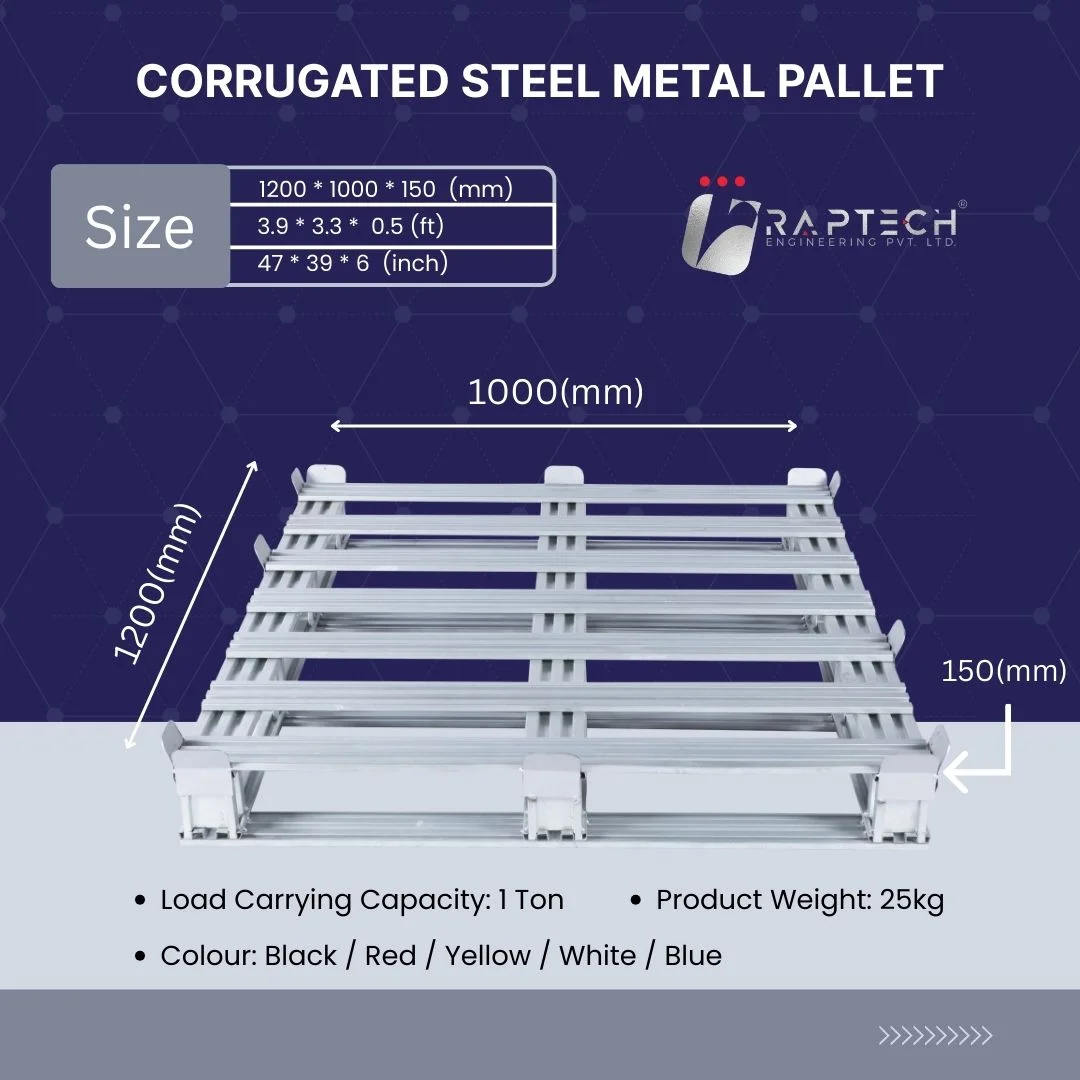

Corrugated Steel Metal Pallets are strong, durable, and reusable platforms designed for heavy-duty material handling and storage. Made from high-quality corrugated steel, they offer excellent load-bearing capacity, resistance to moisture and impact, and are ideal for warehouses, logistics, and export applications.

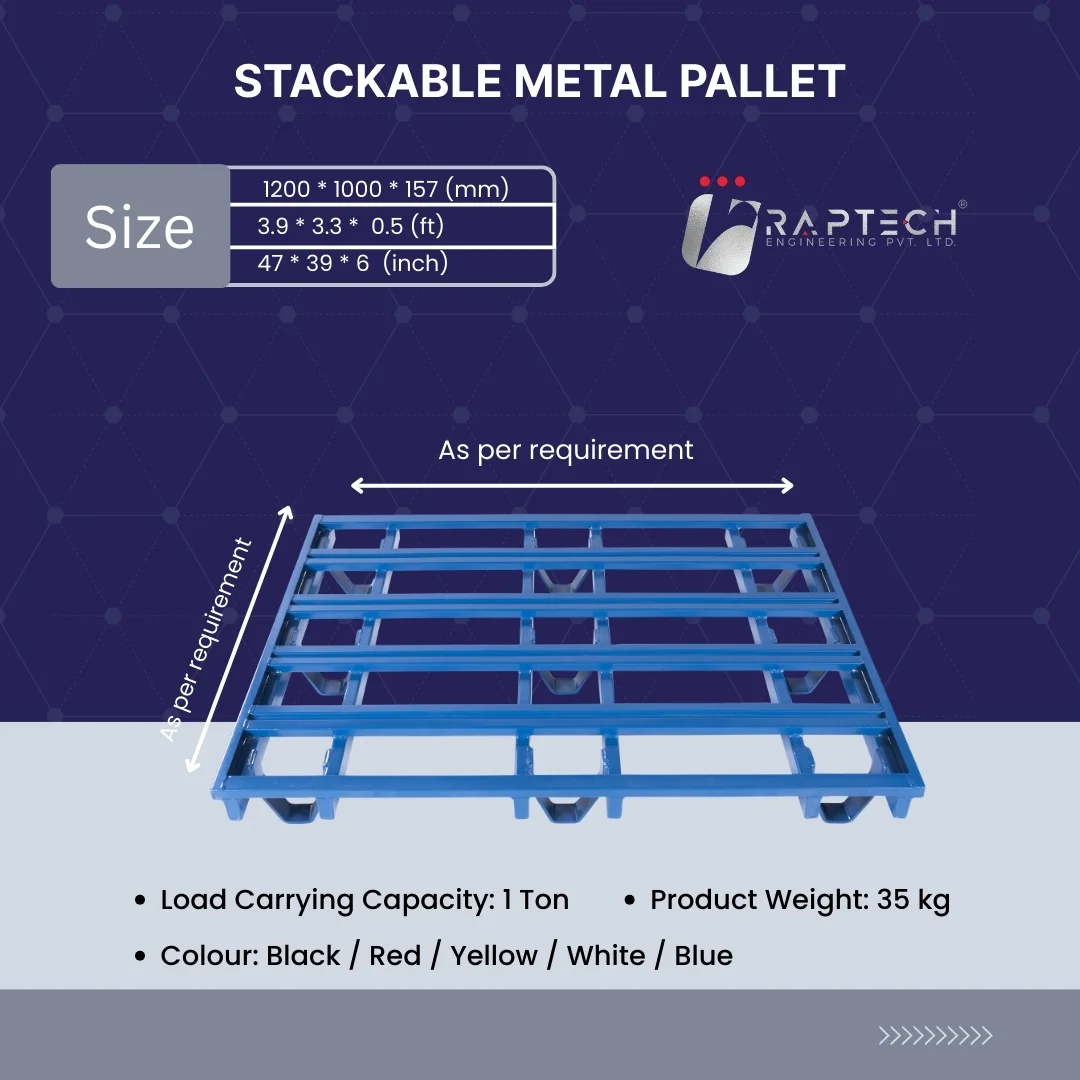

Stackable Metal Pallets are robust and space-saving solutions for efficient material storage and transport. Made from high-strength steel, they ensure durability, stability, and easy stacking when not in use, making them ideal for warehouses, factories, and logistics operations.

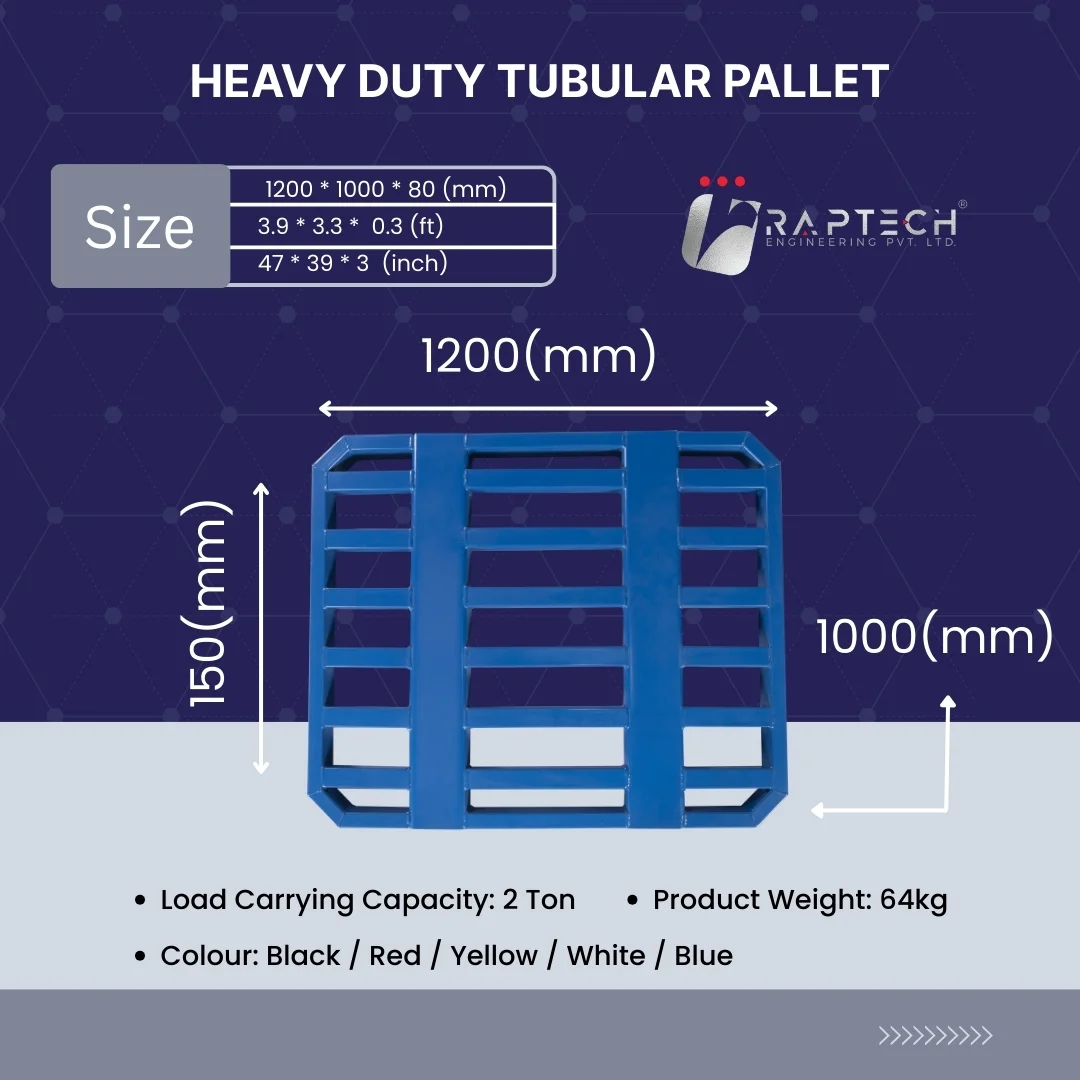

Heavy Duty Tubular Pallets are designed for maximum strength and durability in industrial storage and transport. Constructed from high-quality tubular steel, they offer excellent load-bearing capacity, corrosion resistance, and stability, making them ideal for heavy materials in warehouses and manufacturing facilities.

Heavy Duty Euro Pallets are standardized, robust pallets designed for efficient handling and transport of heavy goods. Made from high-quality materials, they provide excellent strength, durability, and stackability, ensuring safe storage and seamless logistics in warehouses, factories, and supply chains.

Handling and transporting transaxles—complex automotive components combining the transmission and differential into a single unit—requires careful consideration to ensure they arrive at their destination in good condition. Using pallets is a common and effective method.

A Spoiler Painting Hanger is a specialized fixture used in automotive painting processes to hold and support vehicle spoilers while they are being painted. Spoiler Painting Hanger is an essential tool in automotive refinishing and manufacturing, designed to ensure a high-quality paint job and efficient workflow.

A Front Bumper Painting Hanger is a specialized fixture used in automotive painting processes to hold and support front bumpers while they are being painted. Front Bumper Painting Hanger is an essential tool in the automotive painting industry, ensuring a high-quality finish and facilitating a more efficient painting process.

A Rear Bumper Painting Hanger is a specialized fixture used in the automotive painting process to hold and support rear bumpers while they are being painted. Rear Bumper Painting Hanger is a crucial tool in automotive painting operations, designed to ensure a high-quality finish and improve the efficiency of the painting process.

A Front Door Painting Jig is a specialized tool used in the automotive painting process to securely hold and support front doors while they are being painted. Front Door Painting Jig is an essential tool in automotive painting that ensures a high-quality finish, facilitates efficient handling, and helps maintain a consistent workflow in the painting process.

A Fuel Flap Painting Jig is a specialized fixture used in the automotive painting process to hold and support fuel flaps (or fuel door covers) while they are being painted. Fuel Flap Painting Jig is an essential tool in the automotive painting industry, ensuring a high-quality finish for fuel flaps and enhancing the efficiency and accuracy of the painting process.

An ED (Electro-Deposition) Coating Stay for Bonnet is a fixture used in the automotive manufacturing process to support and hold the bonnet (hood) of a vehicle during the electro-deposition (ED) coating process. ED Coating Stay for Bonnet is a crucial tool in the automotive manufacturing process, providing support, stability, and optimal positioning for the bonnet during the electro-deposition coating process.

Air Bag Clip Checking Fixture is a specialized tool used in the automotive industry to ensure the proper functioning and alignment of airbag clips or connectors. Airbag systems in vehicles are critical for passenger safety, and the integrity of their components, including clips and connectors, is essential for reliable deployment during a collision.

An LH and RH Rocker Panel Checking Gauge is a precision tool used in automotive manufacturing and repair to measure and ensure the correct alignment and dimensions of the left-hand (LH) and right-hand (RH) rocker panels of a vehicle. Rocker panels are the sections of the car body located below the doors and between the wheel wells, and they play a crucial role in the vehicle's structural integrity and aesthetic appearance.

Bentellar Arm Machining Fixture is a specialized tool used in the manufacturing and machining industry to hold and support parts securely during the machining process. It is specifically designed for the precise machining of components with complex geometries or specific alignment requirements. The fixture ensures that the part is correctly positioned and stabilized, allowing for accurate and consistent machining operations.

Hydraulic Clamping Fixture for ADB (Air Dryer Bracket) Casting Machining is a specialized tool designed to hold and secure ADB castings firmly in place during the machining process. The hydraulic clamping system provides powerful and precise clamping forces to ensure stability and accuracy while the casting undergoes various machining operations such as drilling, milling, or turning.

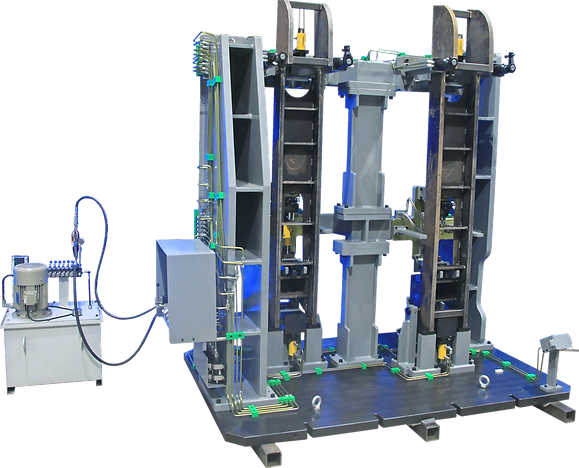

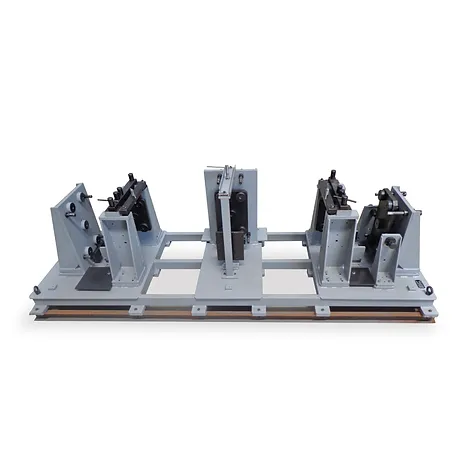

A Hydraulic Clamping Fixture for Track Frame Machining is a specialized tool used in the manufacturing and machining of track frames, which are critical components in construction and agricultural machinery such as excavators and bulldozers. The fixture uses hydraulic power to clamp and hold the track frame securely during machining operations, ensuring precision and stability.

De-flashing Fixture for HVAC (Heating, Ventilation, and Air Conditioning) is a specialized tool used in the manufacturing process of HVAC components, specifically designed to remove excess material, or "flash," from molded or cast parts. Flashing refers to the unwanted material that extends beyond the intended shape of the part due to the molding or casting process. This fixture helps to cleanly and efficiently trim away this excess material to achieve the final desired shape and dimensions.

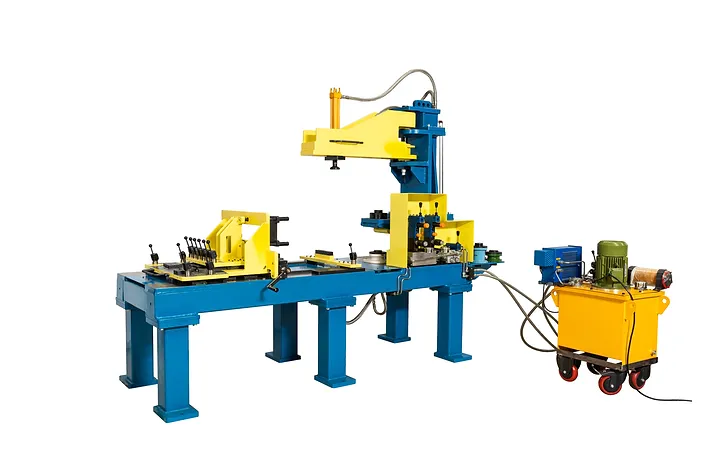

Farm Equipment Welding Fixture is a specialized tool used in the manufacturing and assembly of farm equipment to hold and position parts accurately during the welding process. The fixture is designed to provide stability and precision, ensuring that the components are correctly aligned and securely held in place while welding is performed. This ensures high-quality welds and accurate assembly of farm equipment components.

Road Roller Chassis Welding Fixture is a specialized tool designed to support, align, and secure the chassis components of a road roller during the welding process. The fixture is used in the manufacturing and assembly of road rollers, which are heavy construction machines used for compaction work on roads, asphalt, and other surfaces. The welding fixture ensures that the chassis parts are precisely positioned and held in place to achieve accurate and strong welds, which are critical for the structural integrity and performance of the road roller.

Badge Pressing Tool is a specialized device used to create badges, buttons, or other similar items by pressing two or more components together. This tool is commonly used in the production of custom badges, promotional buttons, identification tags, and other personalized items. The pressing tool helps in assembling these items by securely attaching the badge face, backing, and any other components using pressure.

Steering Cockpit Assembly Handling Tool is a specialized piece of equipment designed to support, position, and maneuver steering cockpits or assemblies during the manufacturing, assembly, or maintenance processes of vehicles. The steering cockpit, which includes the steering wheel, dashboard, and associated controls, is a critical component in vehicles, and the handling tool ensures that these components are accurately and safely managed throughout their production lifecycle.

Wheel Arch Pressing Roller is a specialized piece of equipment used in the automotive manufacturing and repair industries to shape and form the wheel arches of vehicles. The wheel arch, which is the curved part of the vehicle body that surrounds the wheel, needs to be precisely shaped to ensure proper fit and function. The pressing roller helps achieve this by applying controlled pressure and shaping the wheel arch with high precision.

Suspension Spring Expanding Tool is a specialized device used to safely and efficiently expand or stretch suspension springs, typically found in automotive suspension systems. These tools are designed to make it easier to remove, install, or adjust suspension springs by increasing their length or stretching them to fit or release them from their mounts.

Raptech is renowned as one of India's most trusted manufacturers of material handling, storage systems, and lean logistics solutions. Quality is the foundation of our operations, and we subject our products to thorough testing and inspection to ensure they meet the highest standards of durability and performance.

We understand that a one-size-fits-all approach doesn’t work for everyone. That’s why we provide customizable material handling solutions designed to address your unique business needs. Share your requirements with us, and we'll create a bespoke solution tailored specifically for you.